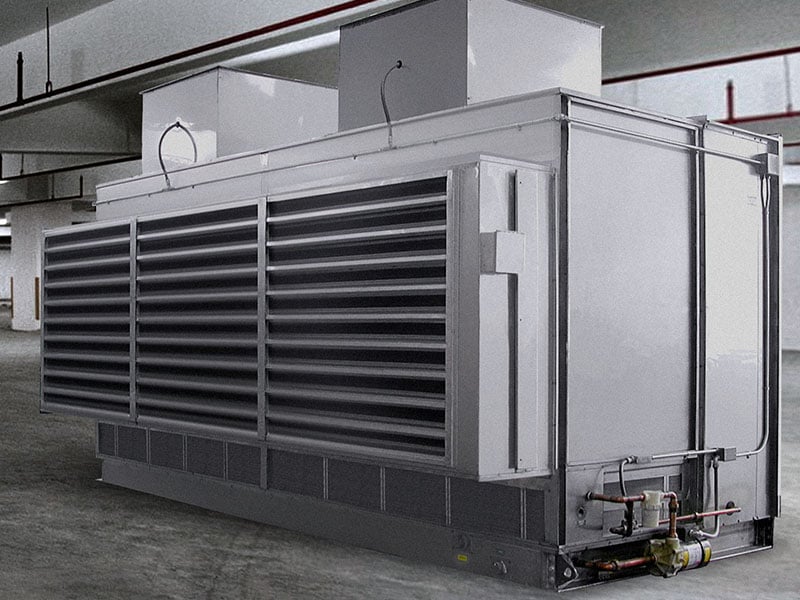

Indirect/Direct Evaporative Cooling Units

Indirect Evaporative Cooling

Vertiv Energy Labs has been building indirect evaporative cooling for over 30 years. Over the years, we have designed systems with EER’s exceeding 100. Our indirect evaporative cooling allows engineers and owners to get the efficiency benefit of water evaporation without concern for water carryover into the building. We can design the indirect evaporative heat exchanger to be used for heat recovery when ambient conditions require heating.

Applications include:

- 100% outside air

- Multi-stage systems that combine indirect evaporative cooling with DX

- Chilled water or direct evaporative components.

Indirect evaporative systems perform very well in dry climates with high dry bulb temperatures. Our Indirect Evaporative Cooling Systems are available in many different sizes and configurations and can be customized for any project.

How It Works

With indirect evaporative cooling, there are two opposing airstreams that contact a different side of a polymer heat exchanger. The outer wall of the heat exchanger contacts air that needs to be conditioned before it is delivered to the occupied space. The inner wall is in contact with air that comes from the ambient environment or building exhaust.

Indirect evaporative cooling occurs when water sprayed to the interior wall of a heat exchanger evaporates. When the water evaporates, the heat of vaporization imparts a cooling effect to the outer wall of the heat exchanger. This allows the airstream which contacts the outer wall to be sensibly cooled.

Other components include a recirculating pump, spray nozzles and a water sump that deliver water to the inside of the heat exchanger.

Why Our Indirect Units Are Better

Our indirect evaporative cooling polymer has been tested for capacity and reliability for over 30 years. The mechanism we use to bond each individual tube to the header is a special chemical process. With this process the bond between the components is stronger than the surrounding polymer. This is in contrast to other manufacturers who use an epoxy gel to seal around each tube. The result is a less reliable seal and increased chances for leaks and performance loss. We use only stainless steel to form the indirect evaporative cooler casing for maximum corrosion resistance and an externally mounted industrial pump, instead of a semi-submersible pump, to re-circulate water over the media. A semi-submersible pump is less reliable and has shorter life expectancy.

Direct Evaporative Cooling

Direct evaporative cooling has gained popularity and rapid acceptance because the process relies on the direct evaporation of water to produce significant cooling and humidification with extremely low energy consumption while eliminating any need for refrigerants. Even with the sophisticated technology now available, direct evaporative cooling is still the simplest, most cost-effective method of cooling and humidification for air.

How it Works

Cooling is provided by the evaporation of water that has direct contact with the air being delivered to a conditioned space. A wetted media like, Celdek or Glasdek, forms the substrate needed to allow the most contact of air to the evaporating water. This media provides a durable, highly wettable, extended surface with low air-pressure drop. It is self-cleaning and consistent in performance.

Vertiv Energy Labs uses only stainless steel to form the direct evaporative cooler casing for maximum corrosion resistance as standard feature.