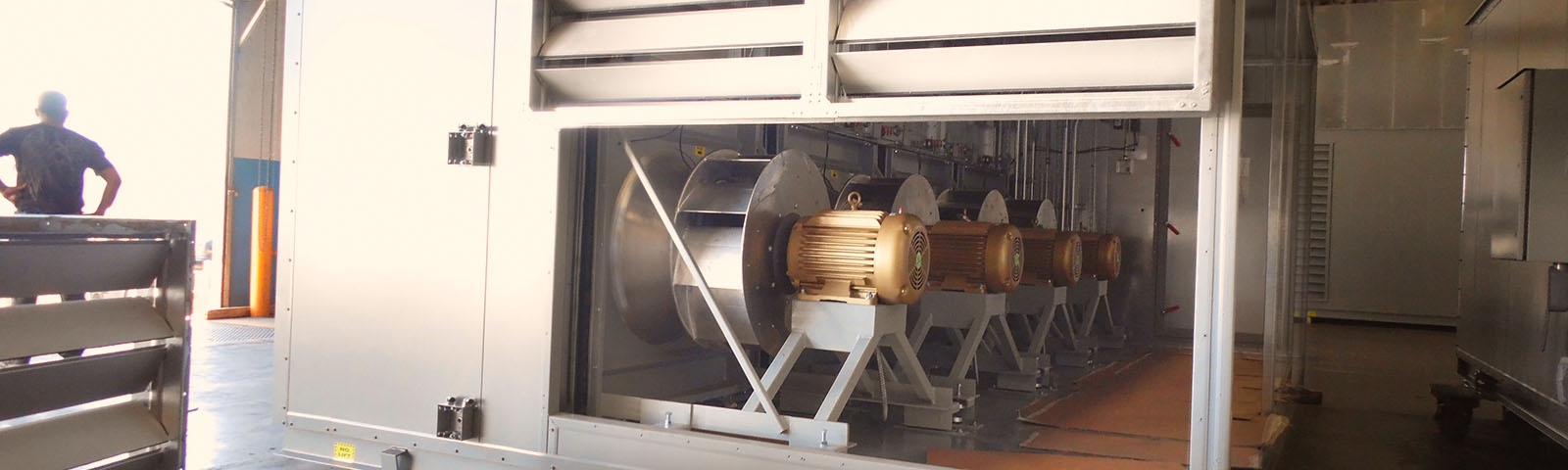

Our manufacturing facility offers a full AMCA Reverberant Room test, which is rare in the industry. Built in 2011, our test laboratory meets all AMCA-required criteria for repeatable testing and is fully AMCA-accredited.

AMCA 210 Air Flow Testing

Good engineering practices allow a manufacturer of custom air handling equipment to estimate system air and sound perfomance. However, fans that perform at a given horsepower and sound level in a single fan test don’t always perform the same way inside a complicated air handling system or in a fan array arrangement. There is only one way to make sure the sytem performs exactly as specified, and that is fro the manufacturer to have accurate and accredited factory testing capability during design, and after assembly, in an environment that closely resembles the actual operating environment.

Factory air flow, sound, and power measurement

A unit sound test cannot provide useful or valid results if accurate system air flow cannot first be established, therefore, perhaps the most important part of any accurate sound test is precise flow measurement data at the specified project static pressure. To do this, our facility features a 65,000 CFM calibrated and certified flow station that accurately provides the needed flow data at the exact static pressure requirements of the project, as well as the air density information required by AMCA 300 and AMCA 210.

Panel Leakage and Deflection Testing

Leaking panel seams waste energy and cause condensation to form at the leak site, creating additional issues with cabinet corrosion and even the formation of unsafe puddles of water on the equipment room floor below the leak. Long life, operator safety, and energy efficient operation are therefore assured only by employing units with a very low leakage rate.

Designed for SMACNA Class 5 or lower leakage rates and low panel deflection, all of our air handling systems can be factory-tested for performance verification at test pressures of 8” or higher.

Our state-of-the-art recirculating Aero Acoustic Laboratory offers the simultaneous measurement of airflow, static pressure, power consumption, and inlet and outlet sound power levels; all to the accuracy required by AMCA 210 and 300 standards. System curve modulation takes place inside the Airflow Measurement Station, which is acoustically isolated from the sound chambers. Large reverberant chambers yield low air velocity across the microphones and heighten accurate sound measurement at frequencies of 50Hz and below.